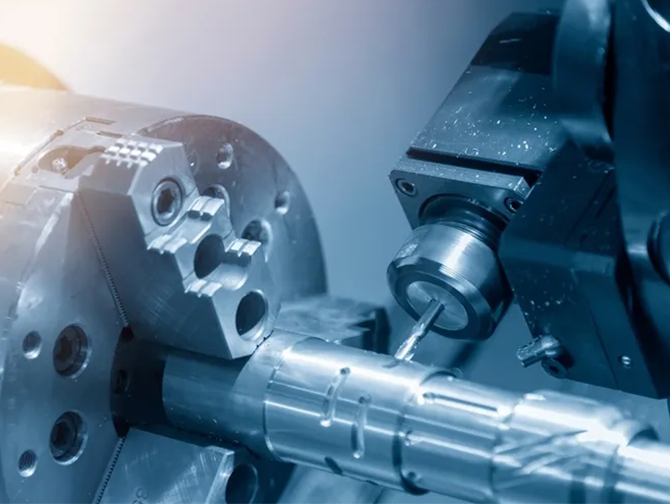

CNC is the abbreviation of "computer numerical control", CNC machining is a kind of manufacturing process that instructs the operation of equipment and tools through programmed computer. This process can control various complicated machinery, such as CNC milling machine, CNC lathe, CNC laser machine, water jet machine, electric discharge machine (EDM), to complete the three-dimensional cutting task.

After activating the CNC system, the product file will be programmed into the software and assigned to the corresponding tools and machinery. These tools and machinery will perform the specified cutting tasks. The CNC machining process includes the following stages:

Design CAD Model

Convert CAD file to CNC program

Prepare CNC machine and tools

CNC Machining operations

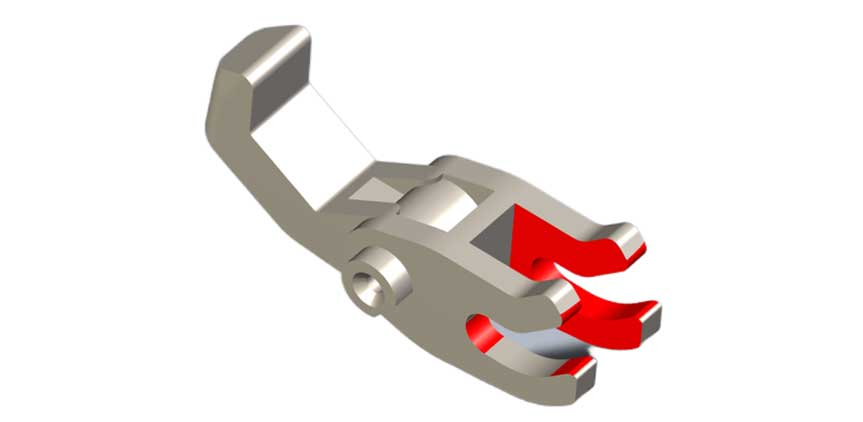

Higher accuracy and precision.

CNC machines have the capability to create complex designs with high accuracy in a short amount of time.

Wide Range of Materials

Choose from over 50 metal and plastic materials.

Custom Surface Finishes

Suitable for many different kinds of substrates, make your parts just the same as real products.

Fast and Repeatable

Quick removal of large amounts of metal material, parts ready as fast as 24 hours.

Cost Saving

Low investment in tooling and preparation costs, economical for parts with simple structure.

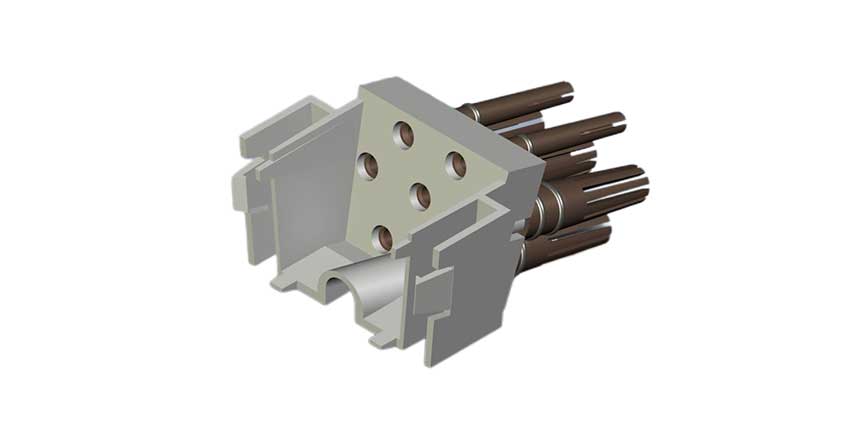

Material | Finishes | Size limitations |

Aluminum, stainless steel, brass, copper, mild steel, alloy steel, tool steel, spring steel, ABS, PC, Nylon, PP, POM, PTEE, PMMA, PE, PEEK, rubber and so on. | Standard, Black oxide, Bead Blast, Chrome plating, Nickel plating, Anodized, Gold plating, Vacuum plating, Laser engraving, Chemical conversion coat, Passivation, Electropolished, Pickling, Dyeing, Bead blast + Anodized color, Electrically conductive oxidatio, Brushed, Spray painting - Matt paint, Powder Coat, Silver plating, Tin plating, Vacuum plating - Matt paint, Silkscreen, Etching, etc. | Maximal part size 1000 mm (40in) Minimal part size 2mm(0.08in) |

Yes, thanks for your update on the projects status,it’s good for me to make our order plan.

Your engineer check the files very carefully,thank you for it, it helps me a lot.

The goods arrived very well, the packing is good, thank you.

We've been worked with GreensTone for many years, there is no failure.

I reached out to GreensTone Electronics to manufacture the circuit boards. After a few discussions, Rebecca could see the community focus of the project and went above and beyond to reduce costs, ensure delivery and filmed elements of the production for educational purposes. Manufacturing offshore isn't as easy as it appears on the surface so it was invaluable to have Rebecca believe in the cause and be an ally in the production working toward the same goal.

Yes, thank you we received the 34x LC VMS TILE 1C REV A earlier this week. The assembly quality is very good.

Thank you for taking time to check it,you are very efficient.

Your engineer is very clever,thanks for the help to check the file's problem.